Our Products

Designing Safer, More Sustainable Solutions

We invest in products and materials designed to deliver eco-conscious and practical solutions for our customers.

RPM is undertaking a proactive, innovative project targeting more than 20 chemical compounds for elimination or substantial minimization globally from product formulations through, among other strategies, replacement with more sustainable alternative substances. This highly collaborative effort among sustainability, regulatory, technical and legal team leaders will make our products even safer and more sustainable for our employees, our customers and the environment. Ultimately, our continued development and expansion of more eco-friendly technology will also give us a competitive commercial advantage. This project signifies RPM’s enduring commitment to conducting business by doing the right things, the right way, for the right reasons.

Flowcrete Low-Emission Flooring

Aware of the impact that buildings have on our comfort, health and well-being, CPG Europe is committed to developing solutions that enable the industry to design and construct sustainable buildings that improve user comfort through the eco-design of complete building solutions.

Combining high performance and aesthetics of solvent-free epoxy flooring together with Low VOC Emissions enables us to provide more sustainable and environmental-friendly solutions designed for all types of sectors and needs thanks to their thermal, mechanical, chemical and impact resistance properties, etc.

The Benefits:

- Environmentally Friendly

- Health and Safety

- Comfortable

- UV Resistant

HIGHLIGHT

-

Our Third Annual Global R&D Summit brought together over 450 associates virtually from across RPM to collaborate and share best practices for driving sustainable product development.

-

With Circularity In Mind, We Enhanced And Established New Partnerships with companies that recycle or find practical uses for RPM products that have been discontinued or have exceeded their shelf life.

-

Our Engineered Solutions Are Serving Electric Vehicle (EV) Factory Construction. These include a Euclid Chemical product that reduces water consumption and cement use in EV factory construction, a Carboline solution that provides up to three hours of passive fire protection and a Stonhard product that helps control static in sensitive EV manufacturing environments.

Elara Luxe™ is the latest colorant technology for the cosmetic and personal care industry from DayGlo Color Corp. Elara Luxe fluorescent pigments embody clean beauty standards and define a new class of cosmetic colorants manufactured from all-natural rice protein; a powerful fusion of nature and technology. Elara Luxe is more than 97% plant-based and reiterates our commitment to reduce our impact on the environment.

Sustainably Advantaged Products

We work to develop more sustainable product formulations, reduce excess product packaging and produce many products that have a direct environmental benefit by reducing waste, energy usage or emissions.

Building a Better World also encompasses our desire to help our customers and end-users achieve their own sustainability goals. We develop product lines designed to extend the useful life of products for consumer, industrial and specialty markets focused on restoration and maintenance.

Euclid partnered with Unifi—maker of REPREVE, the world's number-one branded recycled fiber—to develop this new product for its PSI Fiberstrand line of synthetic microfibers. With a low environmental impact, PSI Fiberstrand REPREVE 225 is a fine denier monofilament synthetic microfiber that is manufactured using resourced polyester material from plastic bottles. In fact, for every pound of PSI Fiberstrand REPREVE 225 that is used to reinforce concrete, nearly 10 plastic bottles are diverted from landfills.

Born out of a belief that clean beauty should never have to compromise on vibrancy, the Elara Luxe product line—comprising seven new plant-based fluorescent pigments—empowers formulators and transforms the traditional way of thinking about color in the space. For the first time, clean beauty products can have the intense, rich palette that customers crave. Elara Luxe pigments unlock possibilities to create vivid shades with a breadth and intensity of color never seen before.

Consumers are driving demand for sustainable products that are free from harmful ingredients. The new product line is free of microplastics; supporting both consumers and the environment. Elara Luxe embodies clean beauty standards and defines a new class of cosmetic colorants manufactured from all-natural rice protein; a powerful fusion of nature and technology. All pigments are renewably plant-sourced, inherently biodegradable, non-GMO, vegan, kosher and halal certified.

AlphaGrade™ Leveling Coat is a two-component, bio-based, polyurethane leveling resin.

Features:

- USDA BioPreferred Certified Product

- Bio Content: 64% (Castor Oil Based)

- Post-Consumer Recycled Content: 30% by weight (This is a post-consumer recycled EPDM crumb rubber. Our supplier grounds the recycled rubber content they source and certify for re-use.)

Energy Efficient Products

Our sealants, weatherization, roofing and building products make buildings more energy efficient, which helps our customers reduce their energy use and GHG emissions.

Tremco CPG creates roof coating products that enable reduced energy consumption in the buildings to which they are applied, compared to traditional roofing materials. “Cool roof” coatings such as our AlphaGuard line of products reduce the heat island effect and enhance the ability of buildings to regulate temperature, leading to more efficient energy usage and a reduction in GHG emissions.

Tremco CPG SG200, SG300, SG555 and Tremglaze50 silicone sealants hold Low Carbon Footprint Certification by the South Korean Government’s Ministry of Environment, meeting South Korea’s green building requirements for construction of new commercial buildings. The lifecycle of these sealants also produces fewer GHG emissions than products of the same category.

Carboline provides coatings for the power industry, including renewable energy markets. Carboline's coatings for wind turbine blades provide long-term protection against high-temperature and extreme atmospheric environments, including harsh weather.

Euclid Chemical's Tuf-Strand SF is a fiber designed to replace energy-intensive materials such as conventional metal reinforcing bars (rebar) in a wide variety of building applications. When used in concrete, Tuf-Strand SF fibers promote higher infrastructure durability and safer working environments while reducing or eliminating the need for rebar — a material that can negatively impact the environment.

Research, Development & Innovation

Sustainability-related innovation is embedded in our culture. From creating resilient coatings for wind turbine blades to reformulating products with bio-based materials, our investment in innovation reflects our commitment to sustainability and meeting the challenges of climate change. We aim to advance our products ahead of regulatory changes and truly integrate sustainable solutions into our Building a Better World strategy.

At RPM, the leaders of the research and development (R&D) departments for our businesses are responsible for the management of innovation. We seek to center-lead sustainable product development initiatives through the establishment of our Building a Better World Sustainable Products Subcommittee, comprised of leaders in different capacities across our organization. This Subcommittee reports to the Building a Better World Oversight Committee.

RPM also provides formal and informal incentives to associates for creating, implementing and using more sustainable products and processes. We promote the sharing of best practices and innovative ideas among our companies through our Connections Creating Value program.

R&D Symposiums

RPM hosted its first global R&D Symposium in 2020. Technical presentations and educational sessions focused on nearly 100 product innovation opportunities, and 350 new ideas resulted from the Symposium. We continue to host this event yearly, leading more ideas and innovation opportunities than ever before. We created six innovation platforms that help drive sustainable development throughout the organization:

- Product Stewardship

- Product Durability

- Circularity and Product Recycling

- Packaging Innovation and Recycling

- Products to save energy

- Products to reduce waste

The RPM R&D Symposium in 2022 expanded our mission with the theme “Creating our Future: Growth and Sustainability.” Committees meet quarterly to make progress on the innovation platforms and periodically report results to our four Group Presidents and the Chair of our Building a Better World Oversight Committee.

The R&D innovation platform projects have a shared goal of creating safer and more sustainable products and processes. Our researchers actively work to create products that last longer, prevent damage, use safer alternative chemicals, promote health and wellness and minimize any impact to people and the environment.

Recycling And Reuse

As RPM charges forward with its commitment to Building a Better World, our teams are focused on world-class performance while maximizing material circularity. Whether through partnership with third party recycling operations, refurbishment and reuse of containers, or utilization of post-consumer recycled materials, RPM is continually seeking opportunities to manufacture greener products and reduce waste.

Recycled Packaging

-

Rust-Oleum utilizes more than six million paint cans per year made from 100% post-consumer resin. That’s nearly 3.7 million pounds of plastic put to new use.

-

CPG Europe recently replaced 20,000 new drums with reconditioned drums.

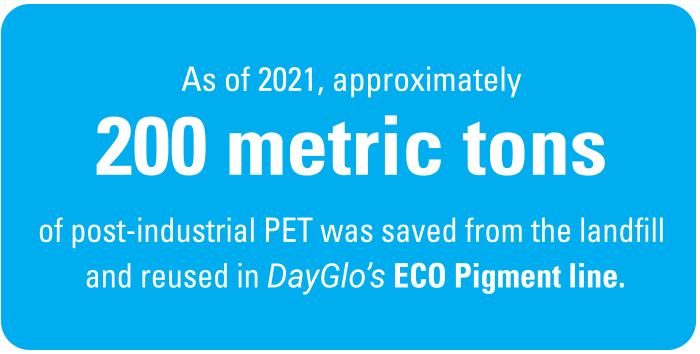

DayGlo upcycles post-industrial polyethylene terephthalate (PET), a waste product left over from the production of plastic containers, such as soda and salad dressing bottles, and grinds it down for use in their ECO Pigment line, which contains upwards of 26% recycled plastic.

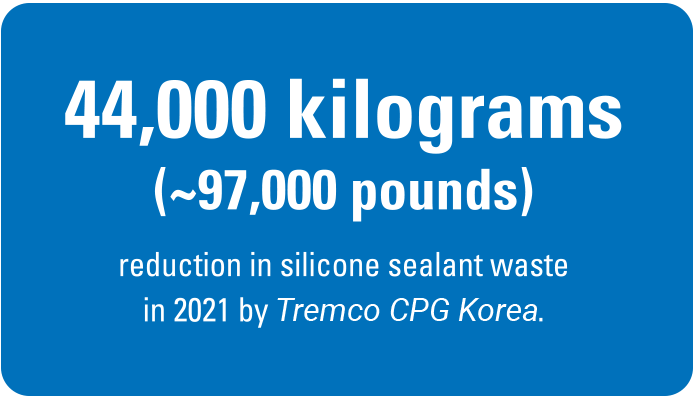

Tremco CPG Korea partners upstream and downstream with our suppliers and industrial customers to reuse and recycle materials.

Stonhard’s Epoplex highway line-striping customers are encouraged to participate in our Intermediate Bulk Container (IBC) pickup program with our IBC tote supplier, which picks up the used totes from customer locations and recycles the steel cages for reuse. In 2021, more than 2,000 totes were picked up for recycling.

At Stonhard’s New Jersey manufacturing facilities, IBCs are sent to reclamation centers to be washed and reconditioned for reuse by the supplier. Since the program’s inception in 2012, Stonhard has avoided landfill disposal of approximately 1,700 IBC totes per year.

Waste Solutions

RPM works to implement creative waste reduction solutions in and through the use of its products. The purpose and formulation of many of Tremco CPG’s products prioritize recycled inputs and reduce lifecycle impacts. Their approach of “Keeping Good Roofs Good”–restoring aging but functional roofs with liquid-applied roofing systems–keeps tons of material out of stressed landfills each year.

VerdeCoat® is helping to drive the food industry’s movement from plastic to paper-based packaging. These high-performance barrier coatings are all free from polyfluoroalkyl substances (PFAS) and can be repulpable, recyclable, or certified compostable for sustainable paper-based food packaging.

Through projects such as the American Coatings Association’s (ACA) PaintCare Program, we promote the extension of our paint products’ lifecycles. RPM participates in this program to help our customers recycle paint easily and safely, leveraging its more than 200 local waste collection facilities across the United States. More than 50 million gallons of post-consumer architectural paint have been collected to date.

Consumer Safety

Our Consumer Group’s R&D teams are working toward developing more water-based technologies and safer product alternatives. We strive to make our products as safe and environmentally friendly as possible for both consumers and associates working in our facilities.

The U.S. Environmental Protection Agency named our Krud Kutter line of cleaning products as a 2021 Safer Choice Partner of the Year. Krud Kutter earned this recognition by increasing its offering of Safer Choice-certified products by 9% and focusing on using concentrates and refillable bottles to reduce plastic use and emissions.

When hazardous wastes are spilled, one of the greatest dangers to people is the spread of pollutants into drinking water sources. Prime Resins’ SoiLok system seals off the soil and holds contamination in one place, preventing the waste from making its way into drinking water sources.

HIGHLIGHT

While Goodbye Natural Cleaners were already “green” when launched in 2021, they were packaged in plastic trigger spray bottles with limited recyclability in many areas. Now Goodbye cleaners are being produced in 100% recyclable bag-on-valve (BOV) spray cans with no CFCs, recreating the line as a totally eco-friendly product line. The new BOV cans also prevent damage in shipping, saving resources to replace leaking bottles.

Like Goodbye products, Un-Duz-It cleaners and deodorizers were originally launched in plastic trigger spray bottles. Most of the formulations are biodegradable and free of phosphates, chlorine, ammonia and hydrocarbons, making them safe for use in boats, RVs and homes. New Un-Duz-It spray products are now sold in 100% recyclable BOV spray cans with no CFCs, giving them an added market advantage of sustainable packaging.